The performance of the cooling system depends on the quality of the thermal paste. A layer made of an unsuitable material can lead to overheating of the processor, even with a powerful cooler.

How to choose thermal paste for the processor and for the video card: what characteristics to pay attention to

When choosing thermal paste for a laptop, a system unit and its components, you should pay attention to the following technical characteristics of this material:

-

Thermal conductivity and thermal resistance (measured values);

-

Plasticity, resistance to temperature changes (non-measurable quantities);

-

Composition.

In addition, it is important to determine whether it is necessary to use thermal paste or whether it is more appropriate to use thermal pads.

Thermal performance

The most serious impact on the performance of a thermal paste is its thermal characteristics. This material has two of them – thermal conductivity and thermal resistance.

Thermal conductivity of thermal paste is a parameter that shows the intensity with which this material removes heat from the processor or computing chip. It is measured in W / (m × K). The higher the thermal conductivity, the better the thermal paste transfers heat from the processor case to the contact pad of the heatsink.

-

For desktop computers and server systems, a thermal paste with a thermal conductivity of 3-5 W / (m × K) is suitable. In this case, the higher the processor performance, the higher the value of this parameter should be. It is worth considering that 'older' chips often heat up much more than modern ones, and therefore they need better thermal paste.

-

For laptops equipped with a low-performance cooling system, thermal grease with a high thermal conductivity value – 6-10 W / (m × K) is required. This will minimize the risks of throttling and overheating of the processor, even if the computer is on your knees and therefore the lower air intakes are covered.

!

Thermal resistance is a parameter, from the operational point of view, the opposite of heat conductivity. The lower the value, the better the thermal paste 'does its job'. However, it does not play a critical role in the choice of material, therefore it is recommended to evaluate precisely the heat conductivity.

Plasticity and resistance to temperature changes

Plasticity and resistance to temperature changes are quantities that are not usually measured. However, they are also important. The values of these parameters can be estimated only indirectly.

The resistance to temperature changes determines how quickly the thermal paste dries and how long it will take to change it. This parameter can be indirectly determined from the operating temperature range of a given material. The wider it is, the higher the stability. So, for example, Zalman ZM-STG2 thermal paste has an operating temperature range of -40 to +150 degrees Celsius. This will ensure that it does not dry out for a long time.

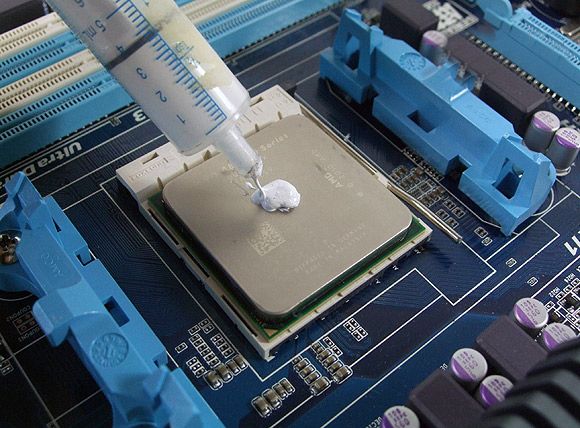

The ease of applying thermal paste depends on plasticity. This parameter can be indirectly determined based on the operating temperature range and thermal conductivity. The wider and larger they are, the thicker the thermal paste will be and therefore the more difficult to apply.

Composition

The composition of the thermal paste directly determines its thermal conductivity. In addition to the polydimethylsiloxane liquid, it contains various metals. And it is their thermal conductivity that determines the thermal conductivity of the thermal paste.

-

Low-cost types of thermal paste, such as KTP-8, are usually made of zinc. This metal has good, but not ideal, thermal conductivity. Such thermal pastes are only suitable for use in older computers with low power processors and low TDP values.

-

Premium thermal compounds are made from highly conductive metals such as tungsten, copper, silver, and gold. Often these materials are even colored in the characteristic colors of these substances.

Such thermal pastes are well suited for powerful computing chips – processors with a TDP of more than 60 W, as well as video card cores.

Thermal paste or thermal pad

Some cooling systems for laptops do not use thermal paste, but thermal pads – special heat-conducting 'cushions' between the computing chip of a processor or video card and the base of the heatsink.

Thermopads are used when the physical size of the chip is too small to contact the base of the heatsink through a layer of thermal paste. They have low thermal conductivity, therefore they are mainly used to cool low-power computer elements (processors and video cards with low performance).

When choosing a thermal pad, it is also worth considering its thermal conductivity and thermal resistance.

But it is worth considering that if the design of the heatsink or the chip allows the use of thermal grease, and not a thermal pad, it is worth using thermal grease.

Manufacturers

Among the manufacturers of thermal paste are:

-

Companies producing KTP-8 and Alsil-3. KTP-8 is the most affordable and widely used thermal paste. However, due to the low thermal conductivity (less than W / (m × K)), it is only suitable for very old computers. Alsil-3 is another option for budget thermal paste. Its thermal conductivity is 1.8 W / (m × K), so it is also suitable only for very old computers;

-

Deepcool, Evercool – produce both budget and premium thermal pastes. Suitable for low-power home and office computers, since they can have a low temperature range of operation;

-

Zalman, Titan, Arctic Cooling, Thermal Grizzly – produce high-quality thermal pastes with good thermal conductivity values, a wide operating temperature range and low thermal resistance. The only drawback is the relatively high price.

!

By the way, Thermal Grizzly also produces quality thermal pads with copper or gold, which are used as heat conductors.

In the next article, our experts will tell you how to choose the right disc for recording.

Attention! This material is the subjective opinion of the authors of the project and is not a purchase guide.