In the modern construction world, hammer drills have long and firmly taken a leading place, having a reputation as universal devices capable of performing many different operations. This device has become an indispensable assistant, regardless of whether a small repair is carried out at home or whether it is a full-fledged industrial construction site. Drilling a small hole, punching a partition, laying a gate, equipping a tunnel for laying sewage – a properly selected perforator with the necessary set of nozzles will perform these and many other operations without difficulty!

- The best manufacturers of rotary hammers – which company to choose

- Types of punchers

- Perforators powered by 220V

- disadvantages

- Battery powered rock drills

- disadvantages

- Pneumatic rock drills

- disadvantages

- Fuel-fired rock drills

- disadvantages

- Punch Selection Options

- Power

- Impact energy

- Drill mount type

- Operating modes

- Maximum drilling diameter

- Additional functions

- Which hammer drill to choose

- How much does a hammer drill cost?

The best manufacturers of rotary hammers – which company to choose

At the moment, on sale you can find a great variety of various perforators, the price level of which can differ 2-3 times. Well-known Japanese and German manufacturers of industrial equipment are rightfully considered the best manufacturers, the quality of their products is not subject to any doubt:

-

Bosch

-

Makita

-

Hitachi

-

Stihl

-

Dewolt

Before making your choice in favor of a particular model, you need to familiarize yourself with the characteristics, as well as take into account all the positive and negative aspects of a particular device. The easiest way to do this is by studying the catalog characteristics of the model, as well as reading the reviews of real buyers on the Internet.

Types of punchers

At first glance, rock drills are virtually indistinguishable from drills. The difference between the two becomes clear when the device is put into operation. Due to its special design, the hammer drill can not only drill holes, but also perform translational impact actions, which greatly simplify destructive work (for example, the destruction of partitions, walls and concrete masonry), and also allow you to make holes in a matter of seconds in those places in which the drill is powerless. Currently, the following types of perforators are distinguished.

Perforators powered by 220V

Simple, easy-to-use and powerful enough devices. The power supply for these models is an ordinary household network, and therefore their real power consistently corresponds to the declared one. They are the most common devices, both in household use and during construction and installation work.

Advantages

-

High power and performance;

-

Democratic cost;

-

Easy-to-use housing, equipped with anti-vibration elements;

-

A large number of additional accessories;

-

Three different operating modes (drilling, impact drilling, impact without drilling);

disadvantages

-

The power depends on the quality of the electricity supplied to the network;

-

The need for regular service due to constant shock loads on the mechanism;

-

The range of use depends entirely on the length of the power cord;

Battery powered rock drills

Devices that are powered by a battery. With a functionality similar to classic models, they are distinguished by increased mobility – not limited by the length of the power cord, which means that you can work even in the field without resorting to the need to use a gas generator. You have to pay for mobility: such devices are much heavier than their network counterparts. In addition, their battery life leaves much to be desired: to work for several hours in a row without charging the 'battery' is unlikely to work.

Advantages

-

Maximum functionality;

-

Independence from an external power source;

-

Ergonomic body;

-

Three different operating modes;

disadvantages

-

The battery life directly depends on the capacity and state of charge of the battery;

-

High price;

-

Significantly higher weight compared to network counterparts;

-

The rechargeable unit is fragile enough: a fall even from a small height can damage the device;

Pneumatic rock drills

Devices, the principle of which is fundamentally different from the two types described above. Such devices use compressed air as a power source, and therefore require a compressor in the immediate vicinity. They are widely used in industry, and especially where there is a developed network in which air is under high pressure. In addition, they have found application in explosive conditions, when the slightest spark can lead to ignition.

Advantages

-

Powered by compressed air;

-

Minimum dimensions and weight of the device

-

They are distinguished by high performance;

-

Allows you to save energy;

disadvantages

-

The range of application is directly limited by the length of the hose;

-

Quite high price;

-

Requires a compressor in the immediate vicinity;

Fuel-fired rock drills

This type of device is extremely original and is better known as a jackhammer. This type of device is based on a compact internal combustion engine running on ordinary gasoline with the addition of oil to lubricate the central piston group. Allows you to work away from the power source and the outlet, with only a can of gasoline at hand. They are widely used in the dismantling of buildings and premises, as well as in the repair of the roadway.

Advantages

-

Profitability;

-

Maximum mobility;

-

Ability to work away from the power source;

-

High power;

disadvantages

-

High price;

-

The ability to inflict too much damage;

-

Increased noise and the presence of exhaust gases during operation;

-

Dimensions;

Punch Selection Options

Power

Reflects the rotational force of the device and the ability to quickly remove demolished concrete and other materials. The higher this parameter, the more productive a particular perforator is. Power is measured in watts at a specific motor speed.

-

For ordinary household use, a device with a power of 600-800 W at 1200-1500 rpm is quite sufficient;

-

If serious installation work and drilling of thick ceilings and walls is required, a more powerful tool is needed, about 1-1.2 kW at 2000-2200 rpm;

Impact energy

A criterion that fully reflects the destructive ability of a particular device. Energy, as usual, is measured in Joules, and the higher this parameter, the easier it is for a hammer drill to destroy concrete, asphalt, brick walls and ceilings, as well as other types of surfaces similar to them.

-

For infrequent household use, devices with an impact energy of 3-8 J are quite sufficient;

-

Industrial equipment is almost always characterized by the ability to make impacts of greater force – about 10-15 J;

-

To carry out dismantling work on exceptionally hard surfaces, a perforator should be selected, the impact energy of which will be at the level of 30-40 Joules;

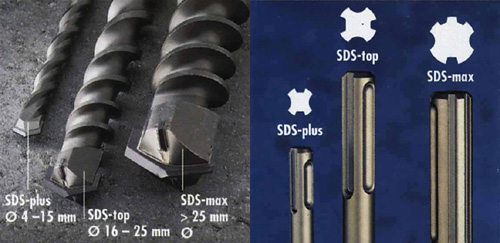

Drill mount type

There are three types of fasteners most common:

-

SDS-Plus. The most common type of element that allows you to use all kinds of blades and chisels, as well as small drills for fixing fasteners. The bore diameter for these models is 25 mm .;

-

SDS-Max. Landing element most often found in professional models. Designed for power work with durable and hard materials. The bore has a diameter of 52 mm;

-

SDS-Top. A very specific type of professional device designed to work with drills with a bore diameter of 16 to 25 millimeters.

Operating modes

Almost all rotary hammers on sale allow you to work in three main modes:

-

Drilling with a blow;

-

Drilling without impact is a direct analogue of an ordinary drill;

-

Impact mode, no drilling;

Maximum drilling diameter

It depends entirely on the type and diameter of the drill used. This parameter is directly related to the power of a particular device: the larger the hole diameter needs to be made, the more powerful a perforator will be required.

Additional functions

Options that make operation as comfortable as possible. As a rule, we are talking about the following options:

-

Reverse – provides the ability to rotate both clockwise and counterclockwise;

-

Overload protection – allows you to keep the device working in case of voltage surges in the network;

-

Brush wear indicator – shows when the brushes are worn out and require replacement;

-

Additional handle – provides the most comfortable grip;

-

Power button lock – allows you to work with the device without pinching the trigger with your finger ;;

-

The drilling depth stop is a useful thing that allows you to make holes of the same depth;

-

Dust collector – an irreplaceable assistant when you need a 'clean' work;

Which hammer drill to choose

-

When choosing an ordinary household punch, you should pay attention to compact devices with a power of 500-700 W and an impact force of no more than 10-15 Joules. Chuck type – SDS +

-

When working away from a DC source, a hammer drill with a similar parameters, powered by a battery with a capacity of 4-5 Ah, is suitable;

-

If we are talking about professional installation work, the choice should be given to a device with a power of 1.2-1.5 kW, an impact force of about 25-30 Joules. Used cartridge type – SDS max;

-

If you have a compressor or a constant air line, a pneumatic rock drill is the best choice. The type and power of the device are selected based on their own needs;

How much does a hammer drill cost?

-

Ordinary household models cost about 5-7 thousand rubles;

-

Their battery counterparts are somewhat more expensive – the most popular models cost about 10 thousand rubles;

-

Gasoline-powered perforators cost about 25-30 thousand rubles;

-

Professional equipment designed for large-scale dismantling works is the most expensive – on average from 40 to 60 thousand rubles;

In the following articles, our experts tell you how to choose the right grinder and the criteria for choosing a disc for a grinder.

Attention! This material is the subjective opinion of the authors of the project and is not a purchase guide.