The comfort in the room, the absence of drafts and other 'delights' of the autumn-winter period entirely depends on how correctly plastic windows are selected. It is they who are a kind of guarantor and protection against colds. However, plastic windows are a complex mechanism, the functioning of which directly depends on the quality of manufacture, as well as on the key elements used in their production. The profile underlying the plastic windows is one knot, and you cannot save on it in any case!

What profile of plastic windows to choose?

When choosing PVC windows, many naively rely on the manufacturer, allowing him to independently choose components for the production of windows. However, it is far from always necessary to talk about honesty – the principle of “minimum investment – maximum value” is as relevant as ever. For this reason, when choosing PVC windows for installation in your home, pay attention to the profile in general and the following features in particular.

Country of origin of the profile

Currently on sale you can find a variety of PVC windows made from profiles produced in all countries of the world. The cheapest and, accordingly, mediocre in quality is considered to be a Chinese or Taiwanese profile – it makes sense to prefer it only if finances are seriously limited. The best is traditionally considered to be the European profile produced in England, France and Germany – these three countries stood at the origins of the production of PVC windows in the middle of the last century, which means that they are the trendsetters who can bring the maximum amount of innovation and ensure the proper quality of their products.

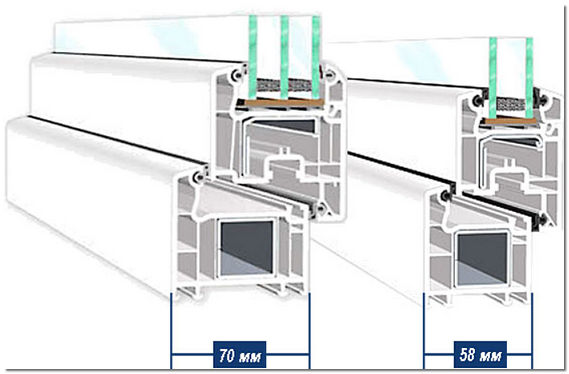

Profile width

The width of a specific profile is a parameter that directly affects the noise, vibration and thermal insulation of a specific window, its mechanical strength and durability. On sale you can find a wide variety of PVC windows, ranging from standard ones equipped with a 58mm profile and ending with wide models based on a profile of 70 and even 90 mm. Windows made on a similar profile width are much more laborious to install, are heavy, and their cost is much higher.

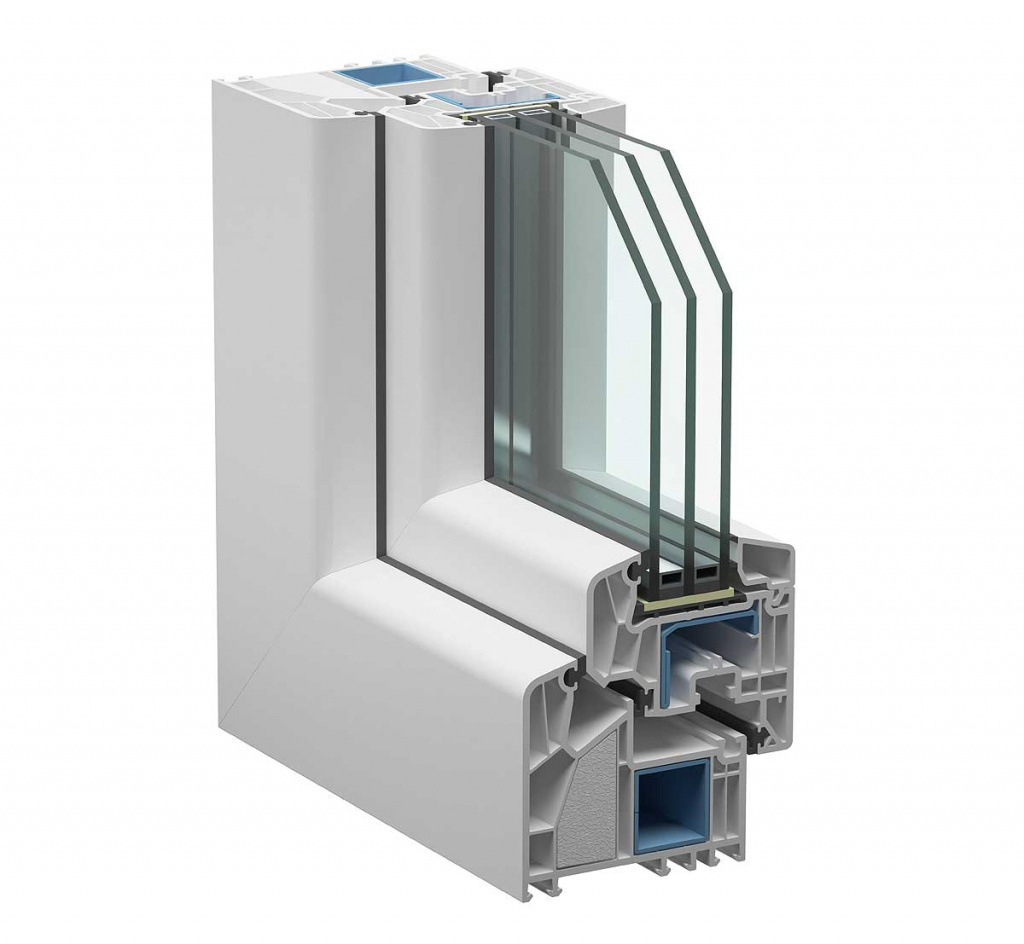

Number of heat-insulating chambers

As a rule, a standard 58 mm profile is equipped with three chambers. The outer one borders on the atmosphere and is designed to smooth out atmospheric processes, equalize the degree of moisture and remove moisture through special channels. The inner chamber serves as a kind of heat insulator, and it also significantly limits the penetration of sound from the outside. The middle chamber complements the functions of the internal one, and also serves as a kind of stiffener, making the overall structure resistant to mechanical stress and torsion.

The above pattern is valid only for a profile with a width of 58 millimeters, while wider models are almost always equipped with a larger number of cameras. For example, a profile with a width of 90 millimeters has almost always six such cameras.

Number of chambers in a double-glazed window

As well as in the case of the number of heat-insulating chambers of a profile, the number of chambers of a glass unit directly affects the characteristics of a particular window. The chamber is an air gap isolated from the atmosphere between two separate glasses, which protects from cold, moisture and extraneous sounds.

!

The more cameras – the better protection and isolation of extraneous sounds and other 'delights' of life in an urban environment. The reverse side of the coin is the greater weight, complexity and laboriousness of installation, as well as the final price of a particular window.

The more cameras – the better protection and isolation of extraneous sounds and other 'delights' of life in an urban environment. The reverse side of the coin is the greater weight, complexity and laboriousness of installation, as well as the final price of a particular window.

Reinforcing steel insert

An element that directly affects the strength of a particular profile, its resistance to mechanical stress and temperature changes – under the influence of direct sunlight in hot summer weather, plastic can 'lead', and it is the metal insert that will retain its geometric shape and the performance of the window as a whole.

ISO 9001 certificate

The quality of a specific profile can be confirmed only in one and only way: the presence of a certificate confirming its quality. This document means that a particular profile model has passed the appropriate tests, and its characteristics are fully consistent with those stated. However, do not flatter yourself: this certificate can be 'bought', and very inexpensively, and therefore a cheap, unnamed profile with a certificate of conformity should at least arouse suspicion.

Top manufacturers

As already noted above, European manufacturers are considered the best, who were at one time the pioneers of the production of PVC windows as a class. These include the following companies:

-

'Veka'

-

'Montblanc'

-

Rehau '

-

'KBE'

-

'Trocal'

-

'Plafen'

Giving preference to the products of this manufacturer, you can be sure that it will last a long time and will not cause a single complaint during operation.

In the following articles, our experts tell you how to choose the right plastic windows, the secrets of choosing a window sill and the features of choosing blinds.

Video for choosing a PVC profile

Attention! This material is the subjective opinion of the authors of the project and is not a purchase guide.