Review of the best according to the editorial board. On the selection criteria. This material is subjective and does not constitute advertising and does not serve as a purchase guide. Before buying, you need to consult with a specialist.

To obtain an airless space in the tank, special vacuum pumps are used. The scope of application of these devices has now expanded significantly, and even at the end of the last century, such equipment could be found in research centers or in the space industry. Vacuum tanks differ not only in size and price, they have different technical characteristics and designs. Recommendations of our experts will help you choose the best model.

How to choose a vacuum pump

Pump power. Most vacuum pumps are powered by electric motors. The speed of pumping out air or gas mixture often depends on their power. But you shouldn't make your choice relying only on this parameter. The higher the motor power, the higher the energy consumption. In addition, using modern designs and technologies, manufacturers are able to increase the performance of the model without increasing the power of the electric motor. Most often, for production purposes, units with a capacity of 0.5 to 12 kW are used.

Residual pressure. In theory, at full vacuum, the residual pressure in the vessel should be 0 mbar. This means that there is not a single molecule inside the container.

- In practice, such a vacuum is unattainable, so the battle is over the lower limit of 0.0005 mbar. Only high-vacuum pumps can reach this level.

- In production, a residual pressure of 0.01-1000 mbar is often sufficient. Low-vacuum models can cope with this task.

Rated productivity. Another important indicator must be considered when choosing a vacuum pump. This is the rate at which a gas mixture is evacuated from a vessel with a limited volume. The faster the vacuum cleaner removes air, the higher its productivity. The range of speed indicators is wide enough, it all depends on the purpose of the device. In some branches of production, 30-40 cubic meters are enough. m / h, and in some areas the productivity reaches 30,000-40,000 cubic meters. m / h.

Design features. The principle of operation has a great influence on the basic parameters of the vacuum pump. The following designs are widely used.

- The best selling are rotary vane oil sealed models with one stage. Their productivity ranges from 4 to 1600 cubic meters. m / h at a residual pressure of 0.1 mbar. They are simple and reliable, but often require maintenance.

- Dry rotary vane models are distinguished by the purity of the vacuum, since no lubricant is used in the design. But it is not possible to achieve a good vacuum level (100-1000 mbar). The pumping speed is 3-500 cu. m / h.

- Water ring vacuum cleaners are capable of pumping out dirty gas mixtures. They are low cost but consume a lot of electricity and water. It is an old type of pump with a produced vacuum of 30-1000 mbar and a pumping speed of 3-45000 cc. m / h.

- A good combination of reliability and vacuum depth (0.5-1000 mbar) can be obtained from diaphragm pumps. They work quietly and are compact in size. But the application is limited to laboratory studies due to insufficient productivity (0.5-16 cubic meters per hour).

We have selected the 5 best vacuum pumps for review. All of them have found their application in our country and received high marks. When compiling the rating, the opinions of experts and consumer reviews were taken into account.

Rating of the best vacuum pumps

| Nomination | a place | Name of product | price |

| Best Low Vacuum Pumps | 1 | Edwards xds | RUB 120,000 |

| 2 | Samson Pumps KE | – | |

| 3 | Busch R5 | RUB 76 346 | |

| Best high vacuum pumps | 1 | Leybold COOLVAC | – |

| 2 | Agilent TwissTorr | RUB 60 0570 |

Best Low Vacuum Pumps

Low-vacuum pumps are widely used in various spheres of production. They are used in food packaging, participate in the operation of equipment, and help conduct laboratory research. The experts have selected several reliable models.

Edwards xds

Rating: 4.9

The British company Edwards has developed a new series of XDS series oil-free (scroll) pumps. The developers have applied an innovative technology of bellows motion input. Thanks to this design, it was possible to completely isolate the working chamber, preventing the ingress of lubricants into it. Experts highly appreciated the high pumping speed (35-95 cubic meters per hour), low noise level, low residual pressure (0.007-0.01 mbar), economical power consumption (0.52 kW). The model becomes the winner of our rating.

The vacuum tank is widely used, from chemical laboratories to areas for spraying coatings. Consumer reviews are positive. The only drawback of units of this series is the high cost.

Advantages

- innovative design;

- stable work;

- ease of installation;

- ease of use.

disadvantages

- high price.

Samson Pumps KE

Rating: 4.8

A worthy competitor to British pumps is the products from Denmark Samson Pumps KE. This series of vacuum cleaners is used for pumping gaseous media from process tanks. Water ring models are in demand in the food and mining industries, in oil production and even in industrial fishing. Experts note the high pumping speed (150-320 cubic meters per hour), since the device operates on the principle of a volumetric hydraulic machine. The pump is compact and durable. In terms of residual pressure, the model is inferior to the leader of the rating (33-100 mbar), and the power consumption of the unit is also higher (4-11 kW).

To the pluses, consumers include high build quality, compactness and inexpensive maintenance. Low vacuum is considered the main disadvantage of Danish pumps.

Advantages

- high-quality manufacturing;

- compact size;

- strength and durability;

- high pumping speed.

disadvantages

- low vacuum.

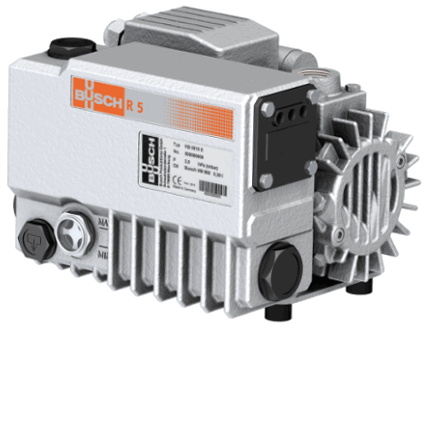

Busch R5

Rating: 4.7

German vacuum pumps Busch R5 are widely used in the food and light industry. Thanks to the rotary vane design, it is possible to create a low vacuum (up to 0.1 mbar). And although the price of German vacuum cleaners is quite high, they are popular in different countries, including Russia. This fact is confirmed by the simultaneous operation of 2.5 million Busch R5 pumps on our planet. For the optimal combination of performance and residual pressure, the model takes an honorable third place in the ranking.

Russian users are offered a variety of models, along with universal pumps in the series there are also highly specialized units. The advantages of consumers include smooth flow and low noise level, simplicity and reliability.

Advantages

- high efficiency;

- variety of models;

- high-quality manufacturing;

- noiselessness.

disadvantages

- high price;

- the scope is limited.

Best high vacuum pumps

High vacuum pumps are often required when developing innovative products. Their task is to create a deep and clean vacuum. Such devices are used in scientific research institutes, in astronautics and medicine. Experts highly appreciated the ability of several units.

Leybold COOLVAC

Rating: 4.9

The well-known Swiss company Oerlicon produces Leybold COOLVAC cryogenic pumps. They work on the principle of a refrigeration unit. The equipment features very clean vacuum, low vibration, high performance. There are 10 modifications in the series, the consumer can easily find the most suitable option. The scope of this unit is wide, ranging from the production of laboratory equipment and ending with electron beam welding. For high quality workmanship and exceptional vacuum purity, the pump becomes the winner of our rating.

Users note that no nitrogen purging is required during operation, the unit can be controlled using a PC. The disadvantages include the high price and the need for regular regeneration.

Advantages

- high purity of vacuum;

- ease of use;

- low vibration;

- wide range of applications.

disadvantages

- periodic regeneration is required.

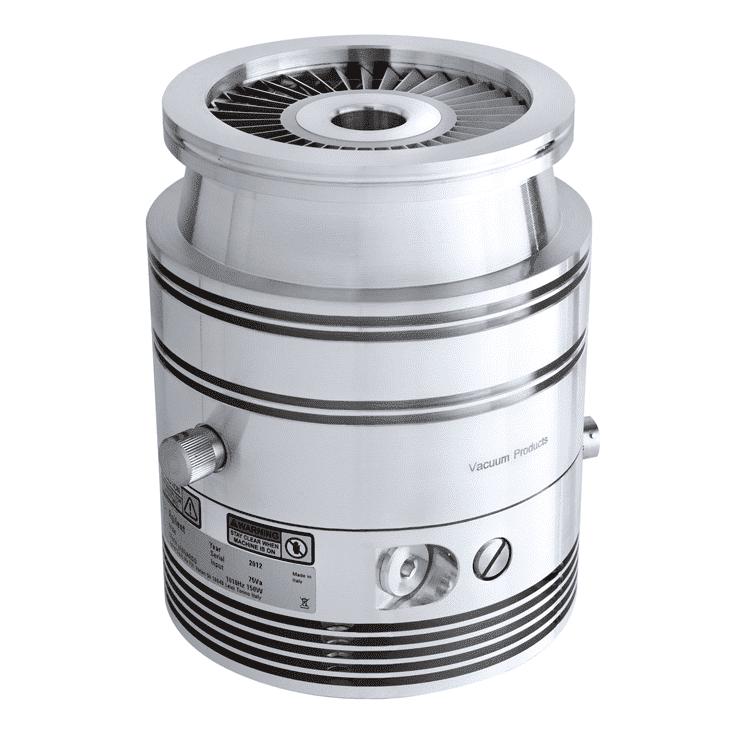

Agilent TwissTorr

Rating: 4.8

The American pump Agilent TwissTorr is not inferior to the winner of the rating in vacuum purity. The turbomolecular model is used in the most high-tech spheres of production and in human scientific activity. The manufacturer managed to achieve high vacuum purity due to improved bearings that operate on dry lubrication. The experts appreciated the low vibration level of the unit, high speed and durability. The American vacuum cleaner is inferior to the European in the richness of the range. The series includes only 5 modifications.

Users are satisfied with the high performance, vacuum quality, reliability, modern design and ease of use. The disadvantages include the high price and limited lineup.

Advantages

- high speed;

- clean vacuum;

- low vibration;

- reliability.

disadvantages

- high price;

- small selection of models.

Attention! This rating is subjective and does not constitute an advertisement and does not serve as a purchase guide. Before buying, you need to consult with a specialist.