Review of the best according to the editorial board. On the selection criteria. This material is subjective and does not constitute advertising and does not serve as a purchase guide. Before buying, you need to consult with a specialist.

For wood processing, thicknessing machines are often used, which have a broaching mechanism and knives on a drum, ensuring safe removal of the top layer. This equipment is used by joiners when planing boards and beams to create the exact size of the workpieces. With the help of a planer, you can independently produce boards from loose logs. Our rating of the best thickness planers has collected the most popular models with good characteristics and many positive reviews. This information will help you choose carpentry equipment for a hobby, workshop or small production.

- How to choose a thicknessing machine

- Advantages and disadvantages of planing and thicknessing machines

- Rating of the best planers

- Metabo DH 330

- Advantages

- disadvantages

- Specialist SRM-2000

- Advantages

- disadvantages

- JET JWP-12

- Advantages

- disadvantages

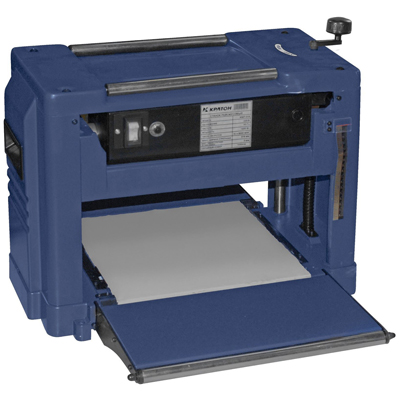

- Craton WMT 318

- Advantages

- disadvantages

- Interskol RS 330-1500

- Advantages

- disadvantages

How to choose a thicknessing machine

In order to correctly choose a thicknessing machine from the products listed in the rating or the available assortment in the store, you need to know the key parameters of the equipment. These include:

- Electric motor power. The indicator varies from 1.5 to 3 kW, which determines the thickness of planing at a time and the ability to work with wood of different density and moisture content.

- The number of sides processed at one time. The device can remove one or two sides at once (the blades at the top and bottom rotate on the shafts), which increases productivity and increases the cost of goods.

- The number of knives on the drum. One shaft can contain from 2 to 4 knives. This affects the processing speed and gouging quality. The four blades are beneficial to operate, but also increase product and service costs.

- Depth of cut per pass. Indicates the height of the layer to be removed when the board is drawn once. The indicator is from 2 to 3 mm. This affects performance at high volumes. For hobbies or periodic activities, the parameter is not critical.

- Knife sharpening side. Single-sided sharpening machines are cheaper, but the tooling will often have to be edited. Double-sided sharpening on equipment is more expensive, but it prolongs trouble-free operation.

- Workpiece width and height. Since the design of the thicknessing machine has a gantry shape, the dimensions of the workpiece depend on the dimensions of the opening. There are models in width that allow you to start a board from 280 to 330 mm, and in height from 140 to 152 mm.

- Chip receiver. If there is a connection pipe, it will be possible to attach a vacuum cleaner or a bag. Otherwise, the sawdust will crumble to the floor and cleaning will be required.

- Minimum thickness. To plan thin strips and picket fence, the minimum workpiece thickness is important, ranging from 5 to 7 mm.

- Shaft speed. It is found from 8000 to 10000 rpm, which affects the processing speed.

- Weight. The machines are available in weight from 26 to 40 kg. Although all of them belong to the category of mobile equipment, but with frequent changes of workplaces, the minimum weight makes transportation easier.

Advantages and disadvantages of planing and thicknessing machines

In addition to the thicknessing machines presented in our rating, planing machines perform a similar function. Let's briefly consider the pros and cons of equipment, comparing it with each other in order to finally understand what type is needed for a particular activity.

|

MACHINE TYPE |

ADVANTAGES |

LIMITATIONS |

|

REISMUS |

+ MOST OF MODELS HAVE A LONGER MECHANISM + LOW WEIGHT 30-40 KG + INCREASED SECURITY + COMPACT DIMENSIONS WON'T TAKE MUCH SPACE IN THE WORKSHOP + LOW ELECTRICITY CONSUMPTION |

-There is a limitation on the height and width of the workpiece -DIFFICULT TO PLAN CURVED PARTS -INCONVENIENT TO WORK WITH BOARDS OVER 1.5 M LENGTH -LESS POWERFUL ENGINES |

|

FOUNDARY |

+ EASY TO HANDLE BOARDS 2-3 M LONG + POWERFUL MOTORS 5-7 kW + NO LIMITATION ON WORKPIECE HEIGHT + CHOOSE A FOURTH + LESS VIBRATION DUE TO POWERFUL STAND |

– TAKES LOTS OF SPACE IN THE WORKSHOP -BAR HAS TO BE PUSHED BY HANDS -MORE DANGEROUS WORK -SIDE STOP NEEDS RIGHT ANGLE ADJUSTMENT – STATIONARY INSTALLATION ONLY |

Rating of the best planers

| Nomination | a place | Name of product | price |

| Rating of the best planers | 1 | Metabo DH 330 | RUB 39,999 |

| 2 | Specialist SRM-2000 | RUB 19 490 | |

| 3 | JET JWP-12 | RUB 26,500 | |

| 4 | Craton WMT 318 | RUB 25,950 | |

| 5 | Interskol RS 330-1500 | RUB 26,950 |

As you can see, the thicknessing tool is more suitable for small logs, 1.5 m long and planing in confined spaces. It is not difficult to get it out of the garage, do the work outside and hide the equipment back. Here is a rating of the best models with excellent characteristics and many positive reviews.

Metabo DH 330

Rating: 4.9

The first place in the rating is given to the German model with two double-sided knives and the ability to plan a maximum width of 330 mm. The thicknessing unit is equipped with a 1800 W motor and rotates the shaft at 9800 rpm. 3 mm is removed from the wood at once. The feed mechanism pulls the workpiece at a speed of 7 m per minute. A folding bed is used to support the long board. To process the rib, it will turn out to start the product 15.2 cm in height. Sawdust is removed through a suction hole with a diameter of 10 cm. A vacuum cleaner can be connected to it to keep the workshop clean. All hazardous parts are located deep in the machine, so nothing threatens the operator. A scale with a narrow, precise pointer helps to determine the height of the size to be set. To prevent the values from getting lost from vibration, a blocker is provided.

Our experts awarded the model first place due to the high smoothness of the processed surface. Carbide knives cut the top layer of wood so efficiently that the board turns out to be as smooth as a mirror, and this is confirmed by the reviews of the masters. If dull, the rig can be re-sharpened. Experienced users share that knives from 'Enkor' and 'Belmash' are suitable for the machine.

Advantages

- confidently pulls the material with a broaching mechanism;

- the speed drops from the load, but the machine continues to turn – it will not stop itself;

- extension tables are particularly durable;

- the size is accurate even without a stopper.

disadvantages

- howls strongly when working;

- high price;

- thickness gauge (lateral) shows incorrect values;

- there is a gap on the hood that needs to be sealed with tape.

Specialist SRM-2000

Rating: 4.8

In second place in the rating is a thicknessing unit with a capacity of 2 kW. Its main advantage is its price, which is difficult for other manufacturers to compete with. The machine has a shaft with two knives and planes 3 mm in one pass. The drum is capable of rotating at speeds up to 8000 rpm. It surpasses the device of other participants in the rating in terms of the height of the workpiece, which is 16 cm.Buyers in the reviews share that the reismus machine easily processes dry wood, but it is harder for it to work with a wet board. Judging by the characteristics and price, this is the best option for a hobby or small-scale home production.

Our experts paid attention to the thicknessing unit due to its weight of 26 kg. This is the lowest in the ranking. Convenient plastic handles on the sides of the case are provided for carrying. A small weight is achieved due to the duralumin frame, but its casting is even and without shells. The machine is practical for those who do not have enough space in the workshop and have to take it outside to work.

Advantages

- emergency shutdown button;

- accurate height scale;

- supporting rollers at the ends of the bed;

- affordable cost;

- protection of the motor from overheating.

disadvantages

- there is no branch pipe for fixing the sturgeon pump;

- soft metal broaching chains;

- pulling and cutterblock at the same height;

- black marks from rubber rollers remain on the wood.

JET JWP-12

Rating: 4.7

We gave the third place in the rating to the thicknessing machine of the Swiss company Jet. Sellers assure that this model has almost no returns. Buyers are satisfied with the quality of assembly and wood processing. The thicknessing machine is powered by a 1.8 kW electric motor, spinning two knives up to 9000 rpm. The maximum width of the board fed to the shaft can reach 31.8 cm, and the height is 15.3 cm. 2.5 mm are planed in one pass. The broaching mechanism is equipped with rubber rollers that feed the workpieces at a speed of 7 m per minute. Buyers love the reviews that the kit comes with two spare knives. This extends the uptime. To maintain cleanliness in the workshop, a branch pipe is provided for the vacuum cleaner.

This model has the largest number of reviews, which is explained by its excellent quality, which is not inferior to the leader of the rating, but the price is two times lower. According to the characteristics with Metabo DN 330, they are almost identical. Equivalent is the cleanliness of the planed surface, where, in most cases, subsequent grinding can be dispensed with.

Advantages

- anti-slip rubber feet;

- supporting rollers on the folding bed and on top of the body;

- holes for fixing to the workbench to reduce vibration;

- engine temperature rise sensor with automatic power off;

- dust collection system.

disadvantages

- there is a slight difference in height between the supply and the receiving table;

- little factory lubricant – after purchase, it is better to disassemble and grease everything;

- noisy at work;

- the aluminum table is gradually wearing off.

Craton WMT 318

Rating: 4.6

The fourth place in the rating is taken by a thicknessing machine from a Russian manufacturer. The unit is produced at a plant in China, but this does not in the least affect its quality. An electric motor with a power of 1.5 kW spins the drum with two knives up to 8000 rpm. Workpiece speed is up to 8 m / min. On soft wood (pine), the machine is able to select up to 3 mm of the top layer at a time. The processing width is permissible up to 31.8 cm, and the height is 15.3 cm. The body is powder coated to protect the metal from corrosion. Owners in the reviews report that the blades on the machine are sharpened, and this allows you to save on tooling.

Our experts have included the thicknessing device in the rating because of its endurance. According to the experience of carpenters, it serves up to 5 years in the workshop without major repairs during everyday use. Over time, you will have to replace the brushes, belt drive and buy new knives, but the engine itself and the chassis are 'not killed'. By the way, the broaching shaft here is made of steel, not rubber, which may be the envy of more expensive models.

Advantages

- knives are not disposable and can be sharpened;

- the specified size is exactly maintained;

- economical power consumption;

- simple adjustment system.

disadvantages

- over time, paint is erased on folding tables;

- no holes for stationary fastening to the workbench;

- to replace the brushes, you need to disassemble the case.

Interskol RS 330-1500

Rating: 4.5

The fifth place in the rating is again assigned to Russian goods, but this time from the Interskol brand. The machine is endowed with a power of 1.5 kW, but despite this it spins the shaft up to 9500 rpm. The model surpasses most competitors in the width of the fed workpiece 330 mm. The design provides for the connection of a dust removal system. In one pass, up to 2.8 mm of the top layer can be removed from the workpiece. The thicknessing unit weighs 33 kg, and recessed handles are provided for rearrangement. Customers in reviews praise the product for its smooth bed, which provides easy pulling of the material.

Our experts liked the thicknessing machine with double-sided knives, for which it was included in the rating of the best. The presence of a blade on each side allows you to reinstall the drum in case of a blunt cutting edge and continue to work. This is optimal for temporary construction projects (finishing baths, saunas, gazebos in a cottage community), where it is not possible to sharpen specific equipment.

Advantages

- button for quick stop of rotation;

- easy replacement of brushes without disassembling the body;

- the width of the received part is up to 33 cm;

- the passage depth is conveniently adjusted.

disadvantages

- you cannot plan boards with a thickness of less than 13 mm;

- there are no spare parts for the feed gear reducer on sale;

- the block rises tightly from the lower position to the upper one;

- bevel gears made of plastic.

Attention! This rating is subjective and does not constitute an advertisement and does not serve as a purchase guide. Before buying, you need to consult with a specialist.