Review of the best according to the editorial board. On the selection criteria. This material is subjective and does not constitute advertising and does not serve as a purchase guide. Before buying, you need to consult with a specialist.

The ceiling between the unheated attic and the living rooms must be additionally insulated. This process is carried out both from above (the material is laid above the ceiling along the logs) and from below (insulation is attached from the side of the heated room and sewn up with decorative panels). We have prepared a rating of the best materials for ceiling insulation, which are suitable for different types of installation. Experts analyzed the characteristics of the insulation and reviews to them, which will help to choose the best material for the price, ease of installation and insulating properties.

Rating of the best materials for ceiling insulation

| Nomination | a place | Name of product | rating |

| Rating of the best materials for ceiling insulation | 1 | Mineral wool | 4.9 |

| 2 | Penofol | 4.8 | |

| 3 | Expanded polystyrene | 4.7 | |

| 4 | Penoizol | 4.6 | |

| 5 | Foil polyethylene foam | 4.5 | |

| 6 | Styrofoam | 4.4 |

Mineral wool

Rating: 4.9

The first place in the rating is occupied by mineral wool. This is the name given to the material obtained by melting basalt rocks, therefore, the product can be found on sale under the designation 'stone' or 'basalt' wool. Warming is achieved due to the formation of thin fibers, tightly intertwined with each other. At the same time, the material is lightweight, flexible and highly insulating. Mineral wool is produced in rolls or square slabs. It is convenient to choose it for insulation of the ceiling according to the height of the thermal insulation – there are options from 50 to 200 mm. The density of the insulation is from 11 to 200 kg / m³. The higher this indicator, the better the material will retain the cold. Buyers in the reviews share that the cotton wool is easy to cut and it is not required to accurately observe the dimensions – the extra edges are simply squeezed and inserted between the ceiling beams.

Our experts awarded the material the first place in the rating, since mineral wool has one of the lowest thermal conductivity values. Depending on the density, it varies from 0.033 to 0.040 W / mK. Also, this option for insulating the ceiling is as safe as possible, because the cotton wool is environmentally friendly and does not burn.

Advantages

- does not burn at all;

- the insulation is not subject to decay;

- rodents are indifferent to him;

- light weight is optimal for ceiling construction.

disadvantages

- insulation is hydrophobic (absorbs water);

- when installing from below to the ceiling, a sufficient number of supports is required, otherwise it will sag;

- shrinks over time.

Penofol

Rating: 4.8

The second place in the rating was taken by penofol – a material consisting of polyethylene foam and a screen. The reflective part is made of foil, 14 microns thick. Due to this design, the insulation bends easily and follows the contour of the surface. She insulates the ceiling of the house both from the attic and from the residential part. The product is produced in rolls and comes in height from 10 to 20 mm. The thermal conductivity index is slightly inferior to the leader of the rating and is 0.049 W / mK. Buyers in the reviews like the ease of transporting the material, because 50 m is immediately placed in one roll.Penofol is attached to a special glue, which does not have a very pleasant smell, therefore, ceiling insulation should be carried out in a well-ventilated room.

The experts put the insulation in second place in the rating for its reflectivity. Thanks to the foil layer, heat is returned back to the room. In the case of insulation of the ceiling with penofol with two screens, a double effect occurs, contributing to the reflection of the increased temperature in the summer from the room, which will keep it cool.

Advantages

- a small height of 10-20 mm is practical for houses with low ceilings (does not take up a lot of space);

- easily bends and takes any shape, which is convenient for warming embossed ceilings (for example, where the beams go into the room);

- low water absorption;

- reflectivity.

disadvantages

- the side with polyethylene burns and gives off acrid smoke;

- there are many low-quality fakes on sale;

- high price;

- it will not cope on its own in cold regions (you will need to use it in tandem with another insulation).

Expanded polystyrene

Rating: 4.7

The third place in the rating is occupied by expanded polystyrene, which is a gas-filled material. Insulation is produced from polystyrene and copolymers. Unlike conventional steam treated foam, which results in large cells, polystyrene foam goes through an extrusion process in which the substance is passed through a hole with a small cross-section. Thanks to this technology, a heater with small pores and a homogeneous structure is obtained. When insulating the ceiling, the slabs are cut with a knife. They are 6 times stronger in bending than polystyrene, but still break. But the material is ahead of competitors in terms of density – the minimum value starts from 27 kg / m³. Most often, goods with an indicator of 35 kg / m³ are on sale. It is possible to apply ceiling insulation in liquid form along the lags in the attic, but this requires specialized equipment.

According to our experts, the material has earned a place in the rating due to the large selection of slab height. Available on sale options with 20, 30, 40, 50 mm in cross-section. Also, the thermal conductivity of expanded polystyrene is ahead of the indicators of mineral wool: they will have the same effect with a thickness of 30 and 57 mm, respectively. But in terms of strength and ease of installation, it loses to the leader of the rating. In the reviews, the owners praise the ceiling insulation for the presence of grooves that allow you to mount a solid surface.

Advantages

- not afraid of water and steam;

- does not crumble when cutting;

- homogeneous structure;

- a large selection of cross-sectional options;

- density from 27 kg / m³.

disadvantages

- takes up a lot of space during transportation;

- emits toxic smoke when burning;

- you need to more accurately adjust the dimensions on the ceiling;

- low bending strength.

Penoizol

Rating: 4.6

The fourth place in the rating belongs to penoizol, which is one of the varieties of foam. The material is called urea-formaldehyde foam. It is formed from foam and resin that envelops each cell with air. A hardener (orthophosphoric acid) is added to the composition, so the applied mass hardens. Most often, penoizol is applied in liquid form, for which they hire craftsmen with a special installation or purchase an apparatus and perform all the manipulations on their own. In reviews, users like the affordable cost of insulation and the fact that the material does not create pressure on the walls of the structure. After polymerization of the substance, the lags and beams are not deformed.

We marked this material in the rating as the best for insulating ceilings of a large area and with difficult relief. Penoizol is supplied from the installation in the form of a mass similar in consistency to shaving foam, therefore, the substance fills narrow places and crevices well. But they will only be able to insulate the ceiling from the side of the roof.

Advantages

- the material does not burn;

- finely dispersed foam is not attractive to rodents;

- thanks to feeding in liquid form, any height of insulation can be created;

- a relatively cheap way to insulate the ceiling.

disadvantages

- high water absorption (18-20% by weight);

- additional finishing is required to protect the ceiling from moisture;

- when destroyed, it releases formaldehydes and urea;

- shrinkage and microcracks are possible after solidification.

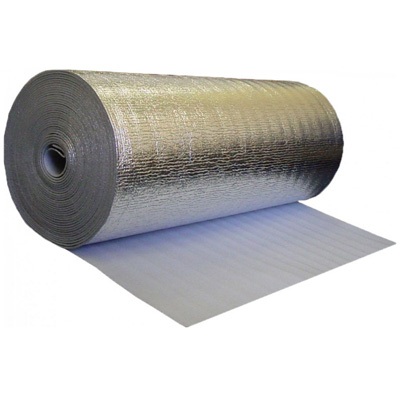

Foil polyethylene foam

Rating: 4.5

Foil-clad polyethylene foam took the fifth place in the ranking. As the name implies, it contains foamed polyethylene laminated with aluminum foil. But the screen is only on one side here. The material for ceiling insulation is produced in rolls and can be: not stitched, chemically stitched and physically stitched. The most famous manufacturer of such a product is the Izolon brand, whose name has become a household name and now refers to the material. Buyers in the reviews like that foil-clad polyethylene foam can be fixed in different ways: with a stapler, self-tapping screws, glue. Due to the screen, up to 95% of the heat is reflected from the ceiling and returns back to the room. Good sound insulation with a small cross section of 5-8 mm. The density varies from 20 to 200 kg / m³.

We included the material for insulation in the rating, as it is well suited for ceiling mounting in wet areas (kitchen, sauna, bathroom). Foil not only reflects heat, but also resists water penetration. There are types of isolon with PET film, which increases the service life of the insulation and prevents corrosion of the screen.

Advantages

- environmentally friendly;

- reflective effect;

- good sound insulation;

- convenient transportation in rolls.

disadvantages

- happens only in small sections of 5-8 mm;

- in cold regions, you will need to use it in tandem with other insulation;

- thermal conductivity 0.051 W / mK.

Styrofoam

Rating: 4.4

In the sixth place in the ranking is a material known to everyone since childhood – polystyrene. For manufacturing, a polymer that is subject to foaming is used. This forms large cells with thin walls. Most of the insulation is gas, so the foam plates are light – they can be mounted on the ceiling both from the inside of the room and from the attic. For installation, a building sealant is used (foam in cans). Blocks are produced with a thickness of 10 to 100 mm, which is convenient for selecting the height of the insulation and the degree of insulation. But when cutting with a knife, the plate crumbles, which delays the laying process. In addition, the joints must be filled with foam, otherwise 'cold bridges' will form there.

The experts added the material to the rating due to the most affordable price in the category. With the help of polystyrene, ceiling insulation does not require a lot of funds from the family budget. Due to the thin walls between the cells, the heat transfer process is significantly slowed down. The masters in the reviews like the product because of the absence of dust during installation, as is the case with mineral wool.

Advantages

- affordable price;

- passes steam;

- there is no shrinkage;

- does not create a load on the ceiling structure;

- various thicknesses (10-100 mm).

disadvantages

- for fixing to the ceiling from the side of the room, mounting foam is needed;

- emits poisonous smoke when burning;

- during installation, time is wasted on sealing the 'cold bridges';

- precise cutting to size is required;

- corners crumble.

Attention! This rating is subjective and does not constitute an advertisement and does not serve as a purchase guide. Before buying, you need to consult with a specialist.