Review of the best according to the editorial board. On the selection criteria. This material is subjective, does not constitute advertising and does not serve as a purchase guide. Before buying, you need to consult with a specialist.

Excavators are self-propelled machines, the function of which is to carry out excavation work using a bucket or several buckets. As such, the work is usually the development of rocks or the implementation of loading bulk materials. Excavators are equipped with both crawler and pneumatic undercarriages, although large models almost always have crawler tracks. This type of equipment is distinguished by a wide variety in terms of size: from fairly compact models, which can often be seen on city construction sites, to real giants commensurate with multi-storey buildings. Such huge machines surprise not only with their appearance, but also with the scale of work with which they regularly cope. Introducing the ten largest excavators in the world.

- The largest excavators in the world

- 10th place – Komatsu PC8000-6

- 9th place – Demag H740OS

- 8th place – Liebherr R9800

- 7th place – Hitachi EX8000-6

- 6th place – Terex RH400

- 5th place – Caterpillar 8750 Dragline

- 4th place – ESh 100/100

- 3rd place – Marion 6360 'Captain'

- 2nd place – Big muskie

- 1st place – Bagger 293

The largest excavators in the world

| Nomination | a place | name | Machine weight | Bucket volume |

| The largest excavators in the world | 10 | Komatsu PC8000-6 | 722 tons | 42 cubic meters |

| 9 | Demag H740OS | 744 tons | 40 cubic meters | |

| 8 | Liebherr R9800 | 800 tons | 47.5 cubic meters | |

| 7 | Hitachi EX8000-6 | 811 tons | 40 cubic meters | |

| 6 | Terex RH400 | 980 tons | 50 cubic meters | |

| 5 | Caterpillar 8750 Dragline | 7500 tons | 129 cubic meters | |

| 4 | ESh 100/100 | – | 100 cubic meters | |

| 3 | Marion 6360 'Captain' | 12,700 TONS | 138 cubic meters | |

| 2 | Big muskie | 13,000 tons | 168 cubic meters | |

| 1 | Bagger 293 | 14,200 TONS | 270 cubic meters |

10th place – Komatsu PC8000-6

Rating: 4.1

The Komatsu PC8000-6 hydraulic excavator is the most powerful model produced by this Japanese engineering firm. It weighs 722 tons and is equipped with a 42 cubic meter bucket. A pair of diesel engines with a total capacity of over four thousand horsepower with electronic control system provide high enough performance for intensive use of the machine in the metallurgical or mining industry. Due to the design of its caterpillar track, the excavator has high maneuverability and smooth running, which is extremely important when working with heavy rock. The travel speed is limited to a minimum of 2.4 kilometers per hour, which is quite natural given its size.

9th place – Demag H740OS

Rating: 4.2

The H740OS excavator from the German heavy equipment manufacturer Demag was developed in 1999 specifically for the needs of the Canadian oil and gas company KMC Mining. Its purpose is to work in extreme conditions with abrasive oil sands. Compared to previous models, the excavator has a wider body and weighs up to 744 tons. The hydraulic machine is powered by two 16-cylinder engines each with a capacity of about two thousand horsepower at 1800 rpm. The crawler track allows you to confidently navigate the shaky sandy surface. The main tool of the excavator is a wide bucket installed in the front part with a maximum breakout force of 2320 kN (kilonewtons), capable of lifting up to 40 cubic meters of sand.

8th place – Liebherr R9800

Rating: 4.

The German Liebherr R9800 mining excavator combines high performance, maneuverability and the ability to work in all conditions. It is equipped with two V-shaped 16-cylinder engines with a total output of 4000 horsepower at 1800 rpm. The machine weighs 800 tons and uses a tracked chassis for movement. The 47.5 cubic meter bucket and powerful hydraulics enable fast loading cycles and large-scale jobs in a short amount of time. The excavator can operate continuously without refueling for three days, during this period of time it consumes 20 thousand liters of diesel fuel.

7th place – Hitachi EX8000-6

Rating: 4.

The EX8000-6 excavator from the Japanese manufacturer Hitachi has been in operation since 2012 and is designed primarily for coal mining. Its length is about 30 meters, height is 10 meters, and the mass of the giant machine is 811 tons. Despite the impressive parameters, the excavator has excellent maneuverability and high accuracy of operations. This is facilitated by an improved hydraulic system with valve reinforcement. Hitachi EX8000-6 power reaches 3880 horsepower. A bucket with a volume of 40 cubic meters and a force of 2230 kilonewtons can extract 75 tons of rock from the ground in just one lift, and in three passes – completely load a large dump truck. The machine has a huge safety margin, allowing it to operate around the clock. Its working resource is about 90 thousand hours.

6th place – Terex RH400

Rating: 4.

The American company Terex has developed the RH400 model for the implementation of complex and voluminous work in deep quarries. It is the largest hydraulic excavator in the world and is also the leader in terms of productivity. The machine weighs 980 tons and creates a pressure of 25.8 Newtons per square centimeter of soil. The dimensions are no less impressive: the length of the giant is 26 and a half meters, the height is just under 14 meters. A tracked platform is used for movement, each of the two pairs of tracks has a width of 8.6 meters. The excavator is equipped with a pair of engines with a total capacity of 4600 horsepower. They can withstand work around the clock until the fuel tank runs out of 15,000 liters of fuel that it holds. The bucket of the machine with a volume of 50 cubic meters weighs 65 tons, it is capable of lifting up to 100 tons of cargo. Thus, only four loading cycles are required to fill a large mining truck. Terex RH400 produces a record 10,000 tons of rock per hour. Thanks to the oil heating system in the hydraulics, the excavator remains operational even in extreme cold conditions.

5th place – Caterpillar 8750 Dragline

Rating: 4.

The excavator Caterpillar 8750 is one of the flagship dragline models. The machine weighs 7,500 tons and is equipped with a maximum bucket capacity of 129 cubic meters, equivalent to half the volume of a 25-meter swimming pool. The huge bucket can lift 345 tonnes with its 132.5 meter boom. The model is available in two different versions: with conventional and direct AC drive. The first option simplifies maintenance, the second is a more economical solution. The excavator is designed to be used in the most difficult conditions, it is able to effectively cope with work regardless of the temperature conditions, including in severe frost.

4th place – ESh 100/100

Rating: 4.

The largest Soviet excavator was manufactured in 1976 at the Uralmash heavy machine building plant, then it was a huge leap forward, the first experience in the history of the USSR in creating such equipment. ESh 100/100 weighed about ten thousand tons (more than the Eiffel Tower), and its height, together with a hundred-meter boom, is comparable to the height of a 25-storey building. This model, released in a single copy, belonged to the category of walking excavators. Its movement was carried out by means of supporting “shoes” driven by a hydraulic drive. This design made it possible to reduce the load on the ground and contributed to the high reliability of the machine. As a power plant, four synchronously operating electric motors were used, each of which had a power of 3600 kW. An excavator bucket with a volume of 100 cubic meters, capable of accommodating a BelAZ truck inside itself, provided a coal mining capacity of up to 17 million cubic meters per year. The power of the bucket traction winch is also amazing – it can move a train several kilometers long. The ESh 100/100 walking excavator was used in the Nazarovsky brown coal deposit (Krasnoyarsk Territory).

3rd place – Marion 6360 'Captain'

Rating: 4.

Built in 1965 for a coal company, the Marion 6360 excavator, called the 'Captain', weighed 12,700 tons and had a bucket capacity of 138 cubic meters, while in the case of light rocks it could hold up to 153 cubic meters. The car was powered by twenty electric power plants, the total power of which reached 15 thousand horsepower. The excavator has been in operation for a long time in quarrying in the southwestern US state of Illinois. It served until 1991, when a hydraulic failure caused a significant accidental fire.

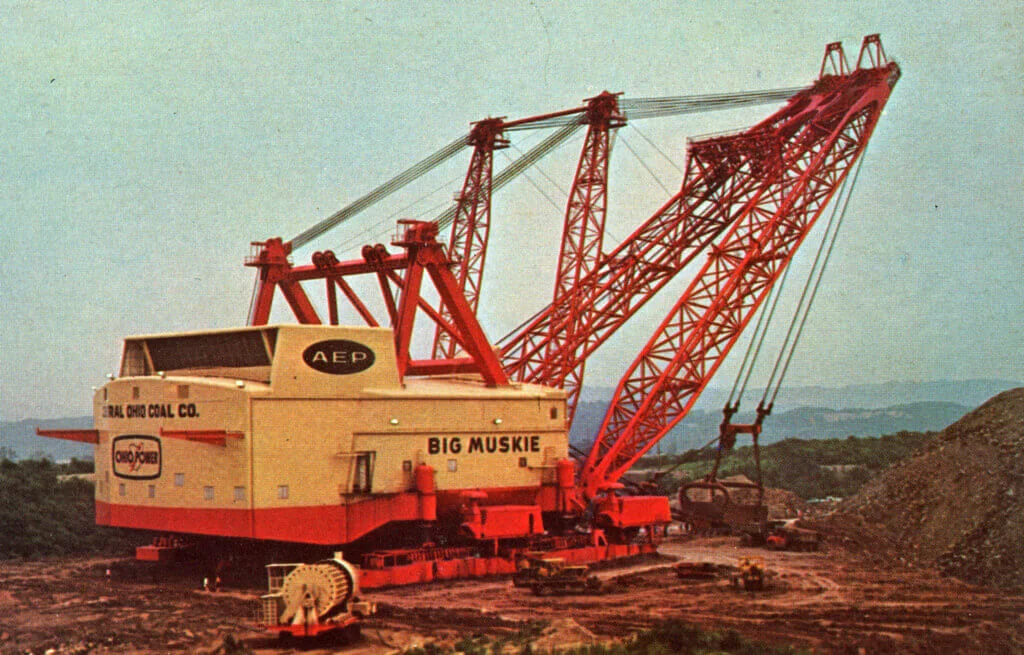

2nd place – Big muskie

Rating: 4.

The weight of the Big Muskie excavator, which bore the official name BE4250W, reached 13 thousand tons. He held two size records at once: as the largest walker and the largest dragline of all that was ever created. Such giants were used in deep quarries, where it was almost impossible for an ordinary crawler excavator to reach. They built Big Muskie right on the job site, having previously installed a reinforced concrete foundation for greater reliability. This fantastic mechanism was approximately 68 meters high and 149 meters long. Unlike the vast majority of similar machines, it was devoid of an engine, instead it was powered by a laid electrical cable with a voltage of 13,800 volts. In the process of performing its functions, Big Muskie consumed a colossal amount of electricity, comparable to the electricity consumption of 27,500 apartments. The main working tool of the excavator – a bucket with a volume of 168 cubic meters could easily fit a couple of buses inside. Over the course of his work, he mined over 20 million tons of coal, digging out more land than was required during the construction of the Panama Canal.

1st place – Bagger 293

Rating: 4.

In the 1970s, German designers at Tenova Takraf were tasked with building machines for coal mining in deep, steep quarries. As a result, the Bagger line was born, and today the Bagger 293 continuous bucket wheel excavator occupies an honorable first place in terms of size and performance. It is 96 meters high, comparable to a 30-storey building, is roughly the length of a pair of soccer fields, and weighs an incredible 14,200 tons. The rotor mechanism of the machine with a diameter of over 21 meters is equipped with 18 buckets with a total capacity of 270 cubic meters. During the day, this mechanical monster is capable of shipping 240 thousand cubic meters of rock, which is equivalent to the size of 96 Olympic swimming pools. The excavator moves around the terrain due to twelve tracked installations, each almost four meters wide. At the same time, the speed of movement is 600 meters per hour, however, this is quite natural given its colossal mass. The Bagger 293 requires 16 and a half megawatts of electricity from sixteen electric motors, which would be more than enough to electrify a small town. The excavator is operated by a crew of five.

Attention! This rating is subjective and does not constitute an advertisement and does not serve as a purchase guide. Before buying, you need to consult with a specialist.