Review of the best according to the editorial board. On the selection criteria. This material is subjective and does not constitute advertising and does not serve as a purchase guide. Before buying, you need to consult with a specialist.

In a private house, the floor of the first floor is very close to the ground and through it cold and dampness penetrates into the room, therefore, high-quality insulation is required between the logs. In multi-storey buildings, an uninsulated basement is usually located below, which also serves as a source of cold. In such cases, the floors in the apartment are additionally poured and pasted over with insulating materials. We figured out which floor heaters are considered the best and provide you with the TOP-10 of the most popular thermal insulation. This will help you determine which substance is best suited for your operating conditions and is acceptable in cost.

- Rating of the best floor insulation

- Basalt wool

- Advantages

- disadvantages

- Foam glass

- Advantages

- disadvantages

- Expanded polystyrene

- Advantages

- disadvantages

- Expanded clay

- Advantages

- disadvantages

- Expanded vermiculite

- Advantages

- disadvantages

- Glass wool

- Advantages

- disadvantages

- Polyurethane foam

- Advantages

- disadvantages

- Polyvinyl chloride

- Advantages

- disadvantages

- Penofol

- Advantages

- disadvantages

- Penoizol-liquid foam

- Advantages

- disadvantages

Rating of the best floor insulation

| Nomination | a place | Name of product | rating |

| Rating of the best floor insulation | 1 | Basalt wool | 5.0 |

| 2 | Foam glass | 4.9 | |

| 3 | Expanded polystyrene | 4.8 | |

| 4 | Expanded clay | 4.7 | |

| 5 | Expanded vermiculite | 4.6 | |

| 6 | Glass wool | 4.5 | |

| 7 | Polyurethane foam | 4.4 | |

| 8 | Polyvinyl chloride | 4.3 | |

| 9 | Penofol | 4.2 | |

| 10 | Penoizol-liquid foam | 4.1 |

When compiling a list of the best heaters, we were guided by the following characteristics: material thermal conductivity, density, susceptibility to combustion or smoke formation, vapor permeability and hygroscopicity. The experts also paid attention to the ease of installation and feedback from the masters.

Basalt wool

Rating: 5.0

In the first place is basalt wool, which is a kind of mineral wool. A substance is obtained from rocks, where raw materials are melted in a furnace with a temperature of 1500 degrees and then, using centrifugal force, they are pulled into threads. The latter has a cross-section of 3-5 microns, so heat is transferred through them very slowly (average value 0.038 W / mK), which serves as an excellent insulation for the floor. Insulation can have vertically or horizontally directed fibers, but a material with multidirectional fibers is considered more effective. Resins and bitumen are used to bind and shape the insulation. The masters in the reviews like how the basalt wool is cut and if you cut a slightly larger size, then it is easy to squeeze and lay it on the floor. When choosing a product, pay attention to the density, varying from 10 to 30 kg / m³.

We marked the insulation as the best because it is absolutely non-flammable. In other building structures (walls, doors), it is used as a fire barrier. If there are wires under the floor, then this is the best means of protection against fire.

Advantages

- does not prick hands during styling;

- easy to lay on the floor;

- if stepped on, it will not be damaged;

- you can cut with a margin and not worry about keeping the dimensions.

disadvantages

- it is necessary to lay a layer up to 100 mm high;

- if placed below the dew point, it will gradually get wet and lose its insulating properties.

Foam glass

Rating: 4.9

In second place is insulation obtained by foaming glass. For this, a silicate material mixed with carbon is used. A homogeneous mixture enters the furnace and heats up to a temperature of 800-900 degrees, after which the glass softens, and the carbon reacts and foams it. As a result, closed pores with thin walls are formed, which poorly transfer heat to one side and cold to the other. The substance solidifies in forms with a thickness of 40-100 mm. It is laid on the logs in the floor, and the joints are treated with a sealant so that “cold bridges” do not form. The thermal conductivity of foam glass is 0.052 W / mK, which is only slightly inferior to stone wool.

Our experts identified the insulation as the best in terms of minimum vapor permeability. In the case of walls and ceilings, the transmission of steam is important in order to remove excess moisture from the room (floors, as it were, “breathe”). But for the floor, complete tightness is important so that moisture from the basement does not get into the living room. The actual indicator of vapor permeability of foam glass is 0.005 mg / (m.h.Pa). In fact, the insulation does not let steam through at all, which means your floors will be dry, despite the humidity in the basement.

Advantages

- absorbs noise up to 56 dB;

- complete environmental safety;

- does not burn;

- resistant to fungal and bacterial attack.

disadvantages

- weak bending strength of 0.4 MPa;

- it is necessary to precisely adjust the sizes of the segments;

- high price;

- joints are required to be treated with a sealant.

Expanded polystyrene

Rating: 4.8

Further in the review, expanded polystyrene, popularly known as polystyrene foam. It is made from styrene copolymers, whose granules are filled with gas. The air dissolved in the polymer mass increases the volume of the granules several times. The process takes place in special block forms in order to give a certain configuration to the material. After filling the matrix to the boundaries, the substance is sintered and cooled. The result is dense, but light blocks (2% styrene and 98% air), the cross-section of which can be from 20 to 100 mm. When insulating the floor, polystyrene is laid between the logs, and the borders are treated with polyurethane foam. The thermal conductivity of the insulation ranges from 0.036 to 0.050 W / mK.

We singled out this insulation as the best for the price. For example, one sheet with a section of 30 mm and dimensions of 1000×500 mm will cost 50 rubles. For 400 rubles. you can buy 4 m² floor insulation, which is enough for a small kitchen or hallway in the house. If the floors require immediate insulation, and the funds for repairs are limited, pay attention to expanded polystyrene.

Advantages

- any section from 20 to 100 mm is on sale;

- does not create a load on the floor due to its low weight;

- does not let water through;

- environmentally friendly material.

disadvantages

- crumbles when cutting;

- the exact dimensions must be observed;

- seams are treated with a sealant.

Expanded clay

Rating: 4.7

This insulation differs from those described above in that it is not made in the form of blocks, but is free-flowing. It is made from slate and clay. Raw materials from small granules are fed into a large rotary kiln installed at a slope. When the drum turns, the pellets fall down and are burnt from the gas nozzle. This increases the strength of the material and removes moisture from it. The thermal conductivity is 0.912 W / mK. Expanded clay is one of the most environmentally friendly floor insulation materials. It does not burn, which is what customers like in reviews. The owners of private houses use the rest of the funds to decorate the landscape, since red and orange pebbles look favorably on black ground. When choosing a heater, pay attention to the size of the fractions, ranging from 10 to 40 mm.

In our opinion, the insulation is the best in terms of ease of installation. You do not need to mark and cut something – the material simply pours out of the bag between the logs in the floor. After that, the surface is leveled. Small pebbles cover all the cracks well, forming a mixture of gravel and air, creating a powerful barrier to the passage of cold. The flooring is covered on top and the floors are ready.

Advantages

- when insulating the floor, there is no need for a sealant;

- no cutting required;

- fills well in narrow areas;

- frost-resistant;

- does not load the floor.

disadvantages

- there should be no cracks in the floor, otherwise it will wake up;

- if for repair purposes it is necessary to remove part of the insulation, then this is more difficult to do than with other materials.

Expanded vermiculite

Rating: 4.6

And here is another bulk material, which can be from fractions from 0.5 to 8 mm. As you can see, it is smaller than expanded clay, therefore it fills the space in the floor even more densely. Vermiculite is a representative of hydromica, which is distinguished by a multilayer structure. It is a mineral that has been learned to swell in order to expand and decrease its mass. The thickness of the embankment of 10 cm of vermiculite is similar in terms of thermal insulation to 1 m of brickwork or 35 cm of a wooden beam. The thermal conductivity of the substance varies from 0.045 to 0.053 W / mK, which is only slightly inferior to mineral wool. In the reviews, buyers are satisfied with the relatively affordable price of the product and the ease of installation in the floor.

This is another best floor insulation with increased fire resistance. The substance is completely non-flammable and retains its shape (does not melt) up to a temperature of 1300 degrees. At the same time, the filler in the floor is resistant to alkalis and acids, therefore, spilled liquids that have leaked through the flooring will not spoil the thermal insulation layer. Therefore, the material is well suited for filling the floors of not only household, but also industrial buildings.

Advantages

- does not rot under the influence of microorganisms;

- does not decompose;

- rodents are indifferent to him;

- insects do not live in it.

disadvantages

- the space in the floors must be repaired from cracks, since fine fractions of 1-4 mm easily spill out.

Glass wool

Rating: 4.5

The review continues with another insulation related to the mineral wool section. Here, the raw material is glass broken or components (soda, sand, borax, dolomite, limestone). The mass melts in the bunker at a temperature of 1400 degrees. After that, the composition enters the centrifuge, where it is blown up with steam to form the finest filaments. When generating fibers, the material is treated with aerosols. The material is then leveled and shaped on the conveyor. At 250 ° C, polymerization begins, giving the fibers strength. As a result, hairs with a cross section of 3-15 microns are formed, and the total thermal conductivity is 0.030-0.052 W / mK. In contact with an open fire, the insulation can withstand temperatures up to 450 degrees.

Insulation is recognized by us as the best, since it has a fiber length 2-4 times longer than that of similar types of mineral wool. This makes the glass wool stronger. When laying blocks on the floor, it stretches and breaks less. Another advantage of long threads is resistance to vibration loads, so the insulation can be used in production where powerful machines and machines operate.

Advantages

- affordable cost;

- easy to cut;

- easy installation on joists in the floor;

- no need to maintain exact dimensions between the beams.

disadvantages

- pricks when laying and causes itching;

- it is necessary to carry out work on floor insulation in a respirator.

Polyurethane foam

Rating: 4.4

This insulation can be of two types: elastic or rigid. The first is known to many as foam rubber. But for thermal insulation of the floor, the second option is better suited. It is supplied from a special installation in liquid form, after which it expands from a chemical reaction with air and polymerizes. At the heart of polyurethane are plastics, which consist of 85-90% gas. This ensures the lightness of the substance and sufficient viscosity. When the filler hardens, it becomes strong and can only be removed mechanically. Reviews show that masters like insulation with a service life of 15-20 years.

Our experts considered the insulation to be the best in terms of filling the space under the floor. Thanks to application in liquid form, the substance spreads well and fills all the cracks with itself. The technician does not need to adjust the size between the beams in the floor, as the product will itself disperse through the channels. To mount the flooring, it remains only to cut off the protruding sections of the foam. When using such insulation, the formation of “cold bridges” or passages for insects is excluded.

Advantages

- resistant to solvents;

- does not cause interest in rodents;

- resists moisture absorption;

- does not rot.

disadvantages

- sophisticated application equipment is required;

- then it is difficult to remove a piece of material from under the floor.

Polyvinyl chloride

Rating: 4.3

This insulation is also called PVC, vinyl or vinol. For laying in floors, a foamed type of plastic is used, which is produced in mats. They can be installed in whole sheets without cutting directly under the flooring or even on top of it when the next layer is the finishing of the floor. The thermal conductivity of the material reaches 0.159 W / mK. Craftsmen praise the product in reviews for its increased resistance to stress. The tensile strength is 40-50 MPa, and when trying to bend the panel, the indicator varies from 80 to 120 MPa.

This insulation stands out for its small section. Mats are produced with a thickness of 2-5 mm, although there are also 19 mm. It is important to use it to insulate floors in an apartment where there is no log and sufficient space, and the use of other aggregates will lead to a reduction in the height of the room. Sheets of 2-5 mm can be laid under linoleum or laminate, which will create an additional heat-insulating layer. Unlike cork backing, PVC is resistant to detergents and salt solutions, so it will last longer on the floor.

Advantages

- the ability to absorb sounds and vibration;

- resistant to aggressive chemical environments;

- tensile strength is 40-50 MPa;

- belongs to the fire-resistant group.

disadvantages

- high price;

- contains light-absorbing dyes;

- may become more rigid after being completely wet (must be stored properly before installation).

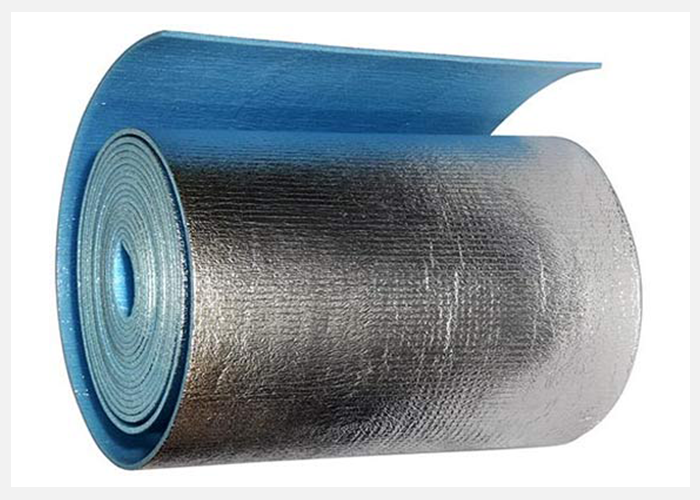

Penofol

Rating: 4.2

Further in the review, floor insulation made of polyethylene foam. Due to the closed cellular structure, the interlayer significantly hinders the transfer of heat. The material is available with a cross section from 3 to 10 mm. It is realized in rolls, for example, with a width of 1.2 and a length of 15 m. Craftsmen note that the insulation is easy to cut to the required size when laying on the floor. Due to the small cross-section, the mats do not need to be cut for laying between the lags, but you can sew the floor with a continuous layer, bypassing each beam. It is also allowed to use insulation on the floors in the apartment, where it can serve as a layer under the linoleum. The thermal conductivity of the insulation is at the level of mineral wool and is 0.039 W / mK.

The chip of the material is the presence of two layers of aluminum, which not only serve as reinforcement, but also effectively reflect the temperature in both directions (the cold from the basement returns back down, and the heat from the room back to the apartment).

Advantages

- resistance to mechanical stress;

- high density allows the use of a smaller layer;

- no need for vapor barrier;

- convenient to transport;

- safe during operation and does not require personal protective equipment.

disadvantages

- high price;

- with a thickness of 10 mm, it reduces noise by only 20 dB.

Penoizol-liquid foam

Rating: 4.1

The review of heaters is completed by polystyrene, which is served not in solidified, but in liquid form. It is sprayed from a special pumping station. The process is not complicated, and the foam sets in 10-15 minutes. After 3-4 hours, it already reaches hardness, and the final set of strength comes after a few days. But this does not in any way affect the ability to lay the floors, since all processes take place under them with the access of air. In reviews, users praise the floor insulation for its elasticity. The substance retains some elasticity and levels out after receiving dents. In addition to thermal insulation properties, liquid foam perfectly resists vibration transmission, so if your house is located close to a metro or tram line, the filler will serve as additional protection against shaking. In terms of thermal conductivity, 5 cm of penoizol is replaced by 12.5 cm of mineral wool.

Liquid foam for the floor stands out for the accelerated installation process, with the presence of specialized equipment. If you are building a large house with an area of 100 m² or more, where you need to insulate the floors in one day, so as not to stretch the process and not slow down other work, use Penoizol. Its masters apply 20-40 m³ per day.

Advantages

- mice do not start;

- the material is environmentally friendly;

- quick installation;

- well withstands shocks and loads.

disadvantages

- specialized equipment is required;

- in some it can cause allergies, but this is individual and quite rare.

Attention! This rating is subjective and does not constitute an advertisement and does not serve as a purchase guide. Before buying, you need to consult with a specialist.